What is DTG Pretreat?

DTG Pretreatment is needed to print white ink onto shirts when it comes to dtg printing. It also gives you more vibrant prints on light color shirts if you use pretreatment made for light color shirts.

How Does DTG Pretreat Work?

It acts like a primer between the shirt and the ink. If you printed ink directly onto a dark shirt you would not be able to see the image at its full potential because the inks would be absorbed into the shirt. I guess it's similar to hair dye. If you dyed your hair light brown but your hair is already black it would most likely not change the color of your hair unless you bleach your hair and then apply the dye. Now you will have the light brown you were looking for. Was that a bad example? Half of it lol. Well, hopefully, you understand what I am saying.

Anyways, It also reacts with the white ink. It makes it kind of tacky making it stick and quickly cure. This happens so that when you go to print your color ink on top it will stick instead of being all runny. You have probably seen this happen if you print with too much ink.

Do You Pretreat white t-shirts for DTG?

Pretreatment for white t-shirts in DTG printing is not always necessary but can still be beneficial. Pretreatment primarily serves to improve ink absorption, adhesion, and durability when printing on dark-colored garments, as it helps the white under base layer bond better with the fabric.

However, when printing on white or light-colored t-shirts, an under base layer is usually not required, and the CMYK inks can be directly applied to the fabric. In this case, pretreatment might not be as crucial.

That being said, some printers and ink manufacturers recommend pretreating white t-shirts to achieve better print quality, color vibrancy, and washability. If you choose to pretreat white t-shirts, follow the same process as you would for dark garments, but use a pretreatment solution specifically designed for light-colored fabrics. Always test your pretreatment process on a sample garment to ensure desired results before proceeding with a full production run.

What is in the Pretreatment for DTG?

What are the Ingredients in DTG Pretreatment Solution?

We downloaded the MSDS From ImageArmor Pretreat and it basically said it is 68-98 % water. and 1-20% calcium nitrates, which are basically Salt. Salt does have the potential to be a skin irritant. It also has a 1-12% vinyl chloride copolymer, which is basically glue. To find out more about DTG Printing Pretreatment click the link.

Below is some of the information that is said on the Image Armor Pretreat MSDS Sheet. I suppose that all the pretreatments are made basically the same. Maybe 1 uses a different type of salt or glue or a different brand of chemical but the majority of it is water. Probably 95% Purified water and 2 and 3 % salt and glue.

3 Composition/Information on Ingredients

· Non-hazardous components:

7789-20-0 USP Purified Water 68-98%

· Chemical characterization: Mixtures

· Description: Mixture of substances listed below with non-hazardous additions.

· Dangerous Components:

15245-12-2 Calcium Nitrate

Skin Irrit. 2, H315; STOT SE 3, H335; Eye Irrit. 2B, H320

1-20%

9003-22-9 Vinyl Chloride Copolymer

Eye Irrit. 2B, H320

1-12%

· Additional information:

The exact percentages of the ingredients of this mixture are considered to be proprietary and are withheld in

accordance with the provisions of paragraph (i) of §1910.1200 of 29 CFR 1910.1200 Trade Secrets.

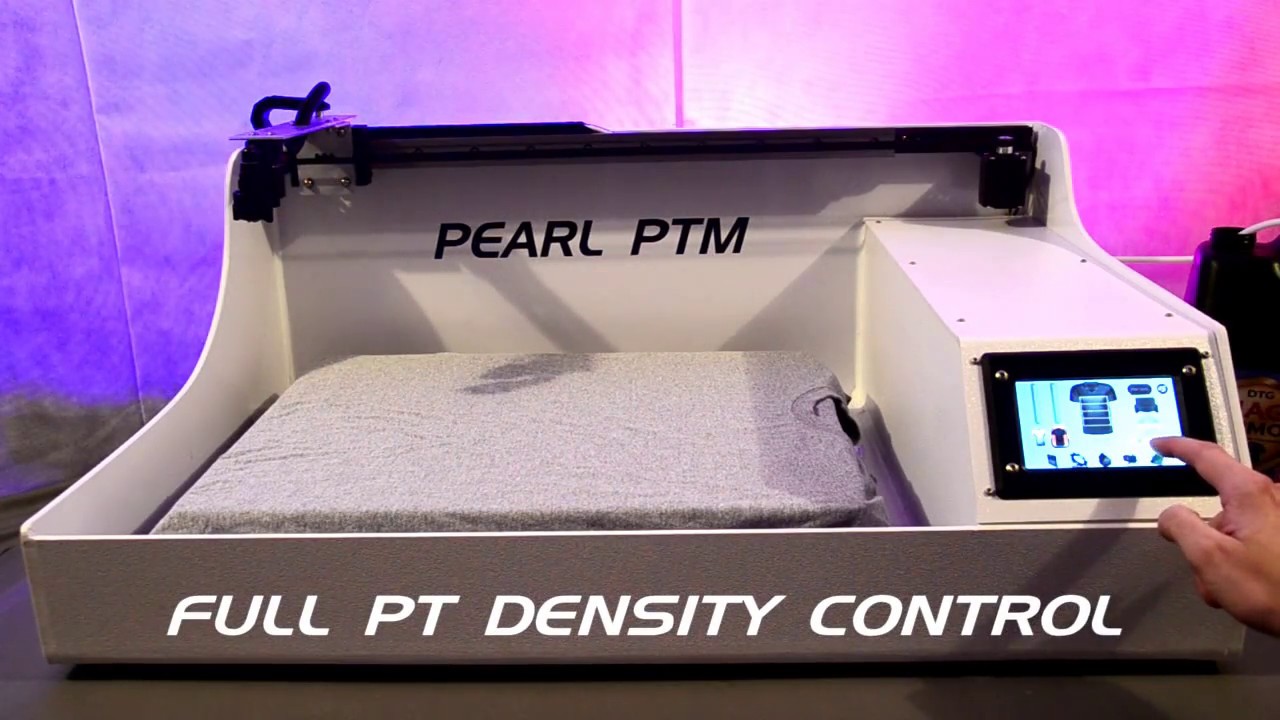

How to apply DTG Pretreatment

We use a DTG Pretreatment Machine. In the beginning, we use to use a Wagner spray bottle but it got really messy. The sprays are also inconsistent and you waste a lot of pretreatment. That is why we are happy that we upgraded.

DTG Pretreatment and DTF Printing

Direct-to-garment (DTG) and direct-to-film (DTF) printing are two popular methods in the world of apparel and textile printing. Both methods use advanced printing technology to produce high-quality, vibrant prints on a variety of materials. In this guide, we'll take a closer look at DTG pretreatment and DTF printing, discussing their unique features, benefits, and applications.

DTG Pretreatment

DTG printing involves applying ink directly onto the garment using specialized inkjet printers. To achieve the best results, it's essential to pretreat the fabric before printing. Pretreatment is a crucial step that helps to improve the print quality, durability, and vibrancy of the final product.

Why is pretreatment necessary?

- Ink Absorption: Pretreatment helps the garment fibers to better absorb the ink, ensuring a more accurate and vibrant print.

- Ink Adhesion: It improves ink adhesion, preventing the ink from spreading or bleeding on the fabric's surface.

- Durability: Pretreated garments have better washability and longevity, as the ink bonds more effectively with the fabric fibers.

Pretreatment Process:

- Choose the right pretreatment solution: The choice of pretreatment solution depends on the fabric type and the desired print quality. There are different pretreatment solutions available for light and dark-colored garments.

- Apply the solution: The pretreatment solution can be applied manually or using an automatic pretreatment machine. Ensure even coverage across the entire area to be printed.

- Dry the garment: After applying the pretreatment solution, the garment must be dried using a heat press or conveyor dryer. This process helps to cure the pretreatment solution, preparing the fabric for printing.

DTF Printing

Direct-to-film (DTF) printing is a newer technology in the textile industry, offering an alternative to traditional DTG printing. Instead of printing directly onto the garment, DTF printing involves printing the design onto a special film, which is then heat-transferred onto the fabric.

Benefits of DTF Printing:

- Versatility: DTF printing can be used on a wider range of materials, including those that are challenging to print with DTG, such as polyester, nylon, and leather.

- Lower Cost: DTF printing typically has lower ink consumption compared to DTG, making it a more cost-effective option for many businesses.

- Less Pretreatment: DTF printing requires little to no pretreatment, reducing the time and resources needed for this step.

DTF Printing Process:

- Design Preparation: The design is prepared using graphic design software and adjusted to the desired size and color.

- Printing: Using a specialized DTF printer, the design is printed onto a PET film with a layer of adhesive powder applied.

- Heat Transfer: The printed film is positioned onto the garment, and a heat press is used to transfer the design onto the fabric. The heat activates the adhesive, bonding the design to the material.

- Cooling and Peeling: After the transfer process, the garment is allowed to cool before the film is carefully peeled away, revealing the finished design.

Both DTG pretreatment and DTF printing have their unique advantages and applications. While DTG remains popular for its high-quality prints and suitability for small batches, DTF printing offers versatility and cost-effectiveness, making it an attractive option for businesses looking to expand their product offerings and reach new markets.

If you have any comments or knowledge about dtg pretreatment please let us know in the comments below.